Reliable Cable and Wire Power Systems

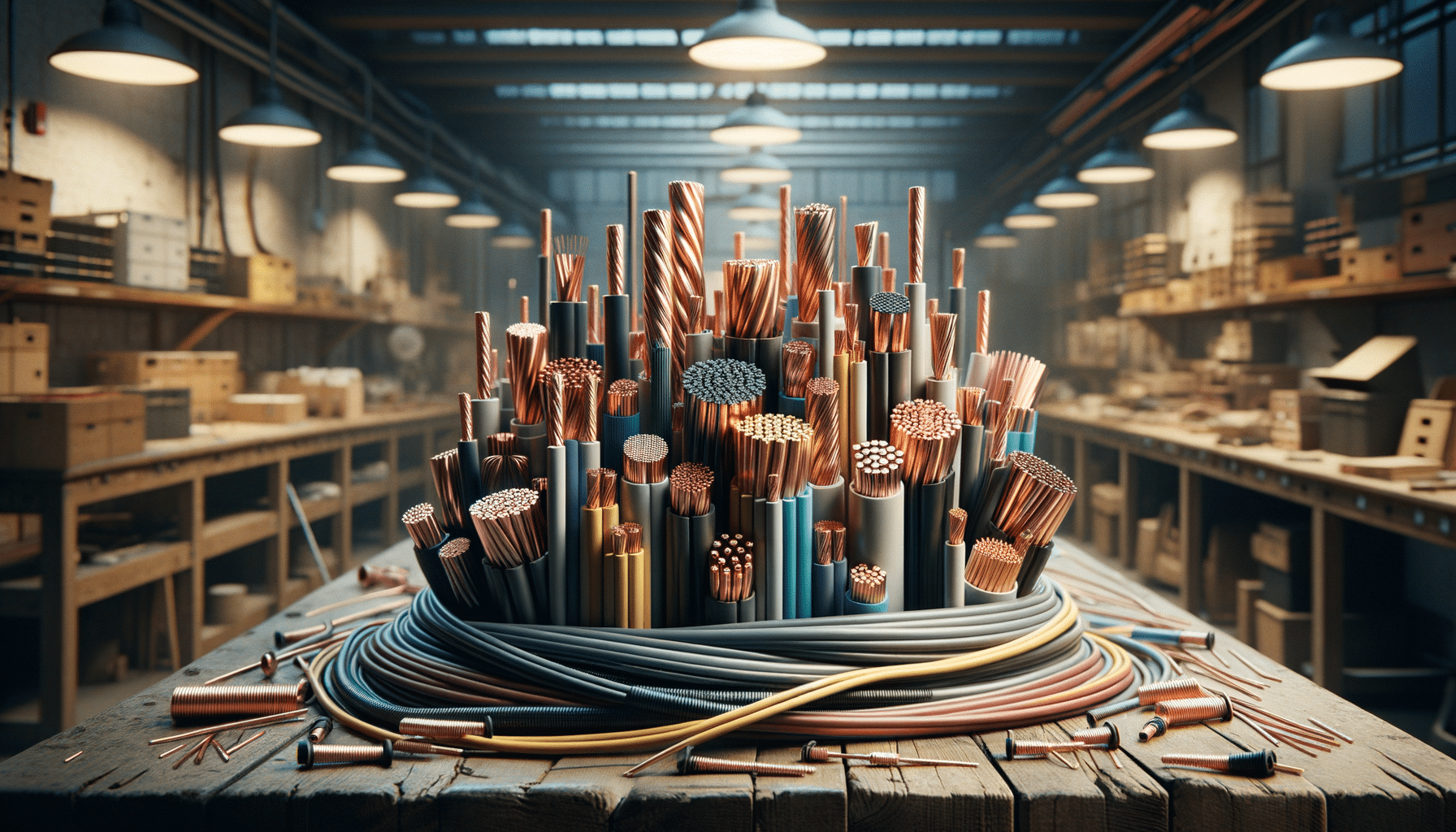

Introduction to Cable and Wire Power Systems

In the modern world, cable and wire power systems are the backbone of electrical infrastructure, providing the necessary connections to distribute electricity across various settings. These systems are integral to residential, commercial, and industrial sectors, ensuring that power reaches every device and appliance efficiently and safely. Understanding the intricacies of cable and wire power systems is crucial for anyone involved in electrical engineering, construction, or maintenance, as it affects the overall performance and safety of electrical networks.

With the growing demand for electricity and the increasing complexity of electrical systems, the choice of cables and wires has never been more critical. Selecting the right type, size, and material can have a significant impact on the efficiency and durability of an electrical system. This article delves into the components, types, and considerations for cable and wire power systems, providing a comprehensive overview for professionals and enthusiasts alike.

Components of Cable and Wire Power Systems

Cable and wire power systems are composed of several key components that work together to transmit electricity efficiently. These components include conductors, insulators, and protective sheathing, each playing a vital role in the system’s functionality.

The conductor is the core of any cable or wire, typically made from copper or aluminum due to their excellent conductivity and flexibility. Copper is often favored for its superior conductivity and durability, while aluminum is lighter and more cost-effective, making it suitable for specific applications.

- Insulation: This is a non-conductive material that surrounds the conductor, preventing electrical leakage and protecting against short circuits. Common insulation materials include PVC, rubber, and polyethylene.

- Sheathing: This is an outer protective layer that shields the cable from environmental factors such as moisture, chemicals, and physical damage. It ensures the longevity and safety of the cable in various conditions.

- Armoring: In industrial applications, cables may be armored with steel or aluminum to provide additional protection against mechanical damage.

Understanding these components helps in selecting the appropriate cable or wire for specific applications, ensuring optimal performance and safety.

Types of Cables and Wires

The diversity of electrical systems necessitates a wide range of cables and wires, each designed for specific applications and environments. Understanding the types available can aid in selecting the right product for any given situation.

Common types of cables include:

- Power Cables: Used for transmitting electrical power, these come in various configurations, including single-core and multi-core cables, depending on the application.

- Control Cables: These are used in automation and instrumentation applications to transmit control signals. They are known for their flexibility and resistance to electromagnetic interference.

- Coaxial Cables: Used primarily for transmitting television and internet signals, coaxial cables have a central conductor surrounded by an insulating layer and a metallic shield.

- Fiber Optic Cables: These are used for high-speed data transmission, utilizing light signals instead of electrical signals, making them immune to electromagnetic interference.

Each type of cable or wire is tailored to specific needs, and understanding these distinctions is essential for any electrical project.

Considerations for Selecting Cables and Wires

Choosing the right cable or wire involves several considerations to ensure it meets the requirements of the application and adheres to safety standards. Key factors include:

- Load Capacity: The cable must be capable of carrying the expected electrical load without overheating. This requires calculating the load and selecting a cable with an appropriate current-carrying capacity.

- Environmental Conditions: Cables exposed to harsh environments, such as extreme temperatures or chemicals, require specific materials and protective coatings to ensure durability.

- Regulatory Compliance: Adhering to local and international standards is crucial to ensure safety and reliability. This includes checking for certifications and compliance with regulations.

- Installation Requirements: The installation process can affect the choice of cable, with considerations for flexibility, ease of installation, and space constraints.

By considering these factors, professionals can select cables and wires that enhance system performance, safety, and longevity.

Conclusion: The Future of Cable and Wire Power Systems

As technology advances, the future of cable and wire power systems looks promising with innovations aimed at improving efficiency, sustainability, and connectivity. The integration of smart technologies and renewable energy sources is reshaping the landscape, with cables and wires playing a pivotal role in this transformation.

Professionals in the field must stay informed about emerging trends and technologies to adapt to the evolving demands of electrical systems. By understanding the fundamentals and staying abreast of advancements, they can ensure that cable and wire power systems continue to meet the needs of modern society.

In summary, cable and wire power systems are essential components of electrical infrastructure, with a wide range of applications across different sectors. Selecting the right products requires careful consideration of various factors to ensure safety, efficiency, and compliance with standards. As the industry evolves, staying informed and adaptable will be key to harnessing the full potential of these systems.