Top Tungsten Carbide Insert Suppliers for Industrial Use

Introduction to Tungsten Carbide Inserts

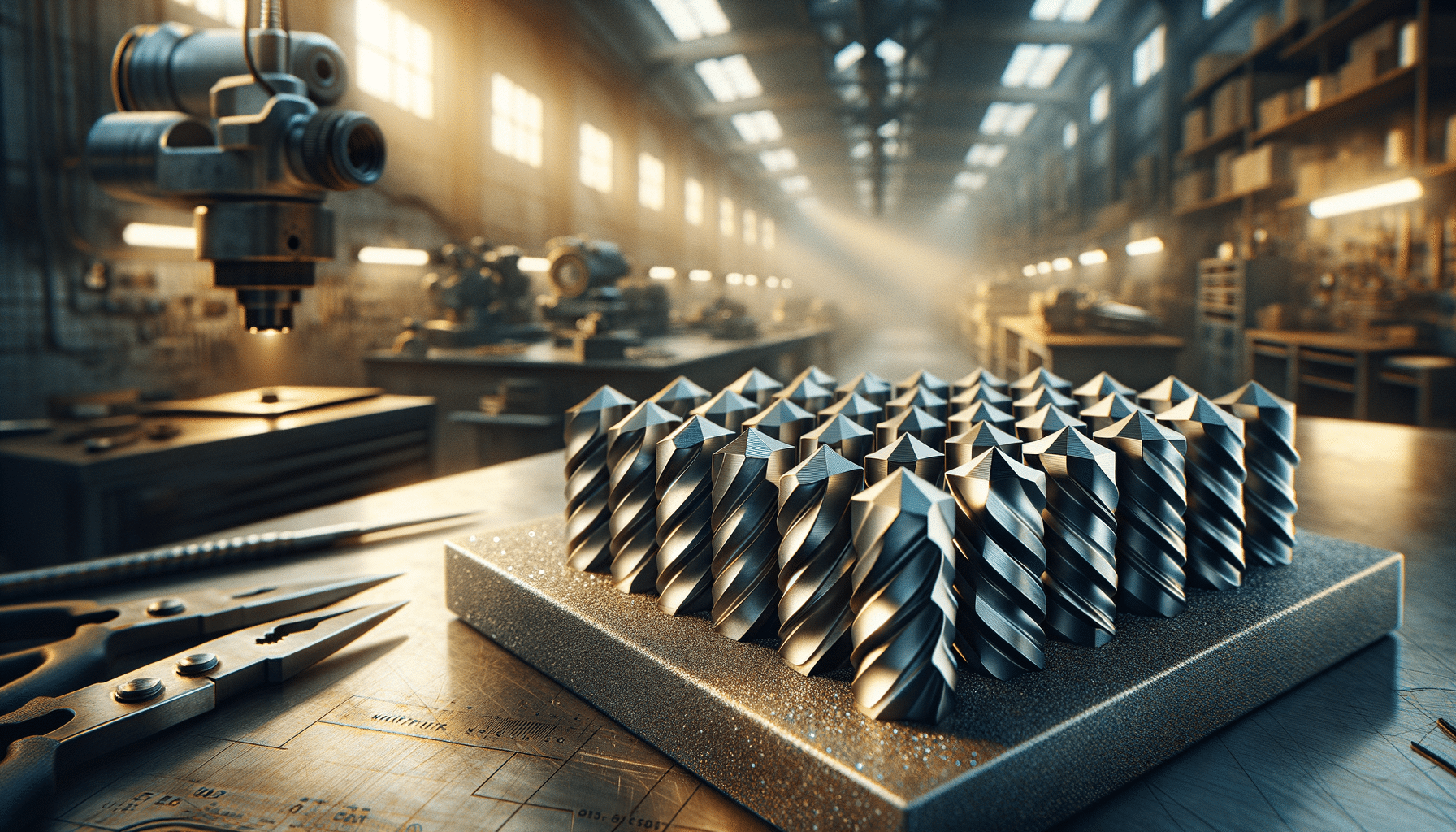

Tungsten carbide inserts are essential components in various industrial applications due to their durability and ability to withstand extreme conditions. These inserts are primarily used in cutting tools and wear-resistant applications, offering exceptional hardness and thermal resistance. Selecting the right supplier for tungsten carbide inserts is crucial for ensuring product quality and performance. This article explores the leading suppliers of tungsten carbide inserts, helping industrial users make informed decisions.

Understanding the Benefits of Tungsten Carbide Inserts

Tungsten carbide is a compound of tungsten and carbon, known for its remarkable hardness, which is comparable to that of diamonds. This unique property makes tungsten carbide inserts a preferred choice in industries such as metalworking, mining, and construction. The benefits of using tungsten carbide inserts include:

- High Wear Resistance: These inserts maintain their sharpness and resilience even in demanding conditions.

- Thermal Stability: They can withstand high temperatures without losing their structural integrity.

- Longevity: Due to their durability, tungsten carbide inserts have a longer lifespan compared to other materials.

- Cost-Effectiveness: Their longevity and performance reduce the need for frequent replacements, saving costs in the long run.

These attributes make tungsten carbide inserts invaluable in enhancing productivity and efficiency in various industrial processes.

Top Considerations When Choosing a Supplier

When selecting a supplier for tungsten carbide inserts, several factors must be considered to ensure the quality and reliability of the products. These considerations include:

- Reputation and Experience: Suppliers with a strong track record and extensive experience are more likely to provide high-quality products.

- Product Range: A diverse product range indicates a supplier’s capability to meet specific industry needs.

- Quality Assurance: Certifications and adherence to international standards are indicators of a supplier’s commitment to quality.

- Customer Support: Responsive customer service and technical support are vital for addressing any issues that may arise.

- Pricing: Competitive pricing, coupled with quality, ensures value for money.

Evaluating these factors helps in identifying suppliers who can deliver reliable and effective tungsten carbide inserts for industrial applications.

Leading Tungsten Carbide Insert Suppliers

Several suppliers are renowned for their tungsten carbide inserts, offering products that meet stringent industry standards. Some of these suppliers include:

- Supplier A: Known for its innovative solutions and extensive product line, Supplier A offers a wide range of tungsten carbide inserts tailored to various industrial needs.

- Supplier B: With a focus on quality and precision, Supplier B provides inserts that are highly rated for their performance and durability.

- Supplier C: This supplier emphasizes customer satisfaction and offers comprehensive support alongside its reliable products.

These suppliers are recognized for their commitment to quality and innovation, making them preferred choices for industries requiring high-performance tooling solutions.

Conclusion: Making the Right Choice

Choosing the right supplier for tungsten carbide inserts is integral to achieving optimal performance and efficiency in industrial operations. By considering factors such as reputation, product range, and quality assurance, industrial users can select suppliers that align with their specific needs and expectations. The suppliers highlighted in this article are among the top options available, known for their exceptional quality and customer support. By partnering with these trusted suppliers, industries can ensure the durability and effectiveness of their cutting tools.