Benefits of Stainless Steel Mesh Coatings in Harsh Environments

Introduction to Stainless Steel Mesh Coatings

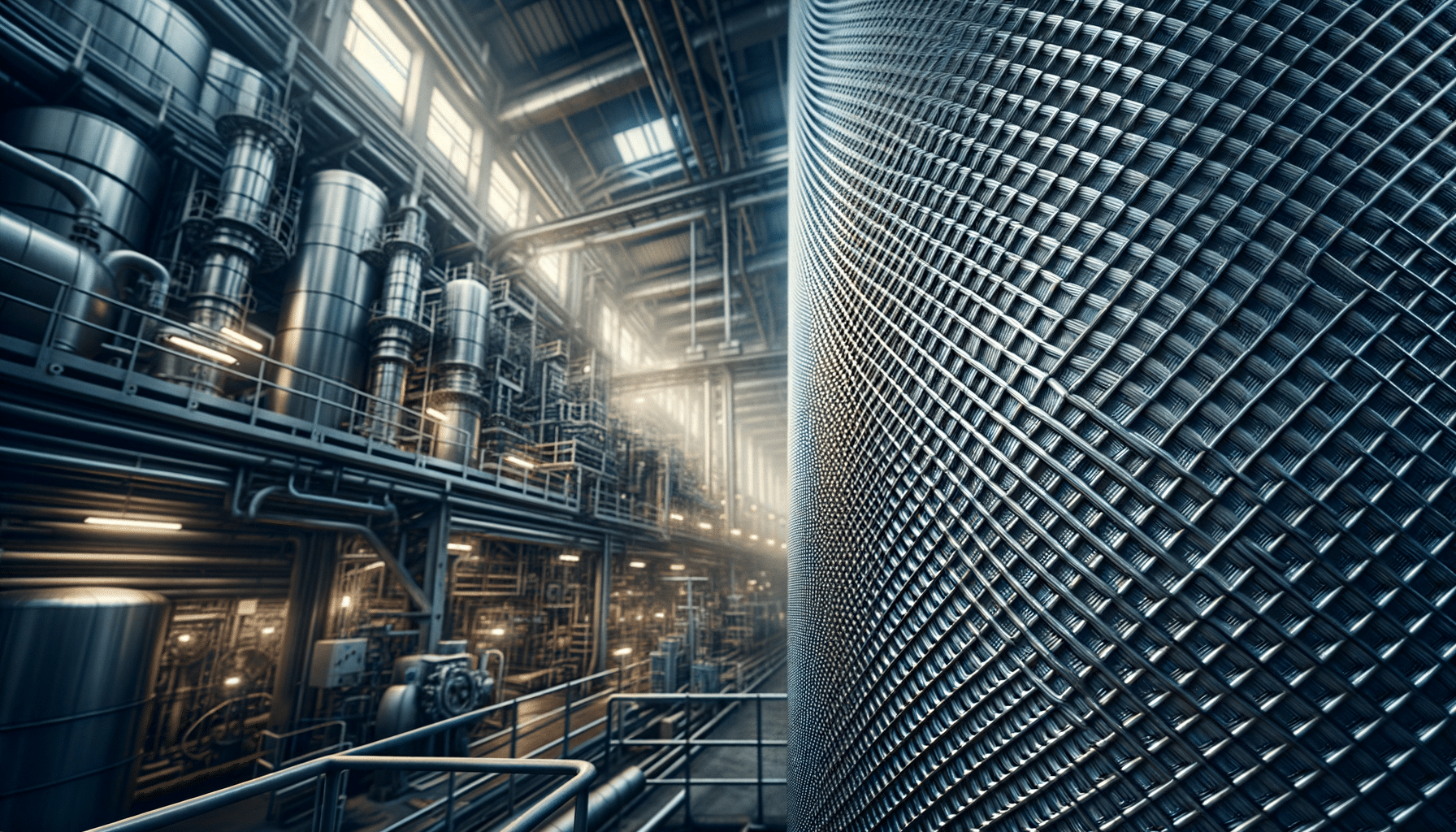

In the world of industrial applications, the need for materials that can withstand harsh environments is paramount. Stainless steel mesh coatings have emerged as a critical solution, offering a robust defense against the elements. These coatings are designed to enhance the durability and performance of stainless steel mesh, making them ideal for a variety of demanding industrial settings. From improving corrosion resistance to supporting filtration processes, stainless steel mesh coatings provide a versatile and dependable option for many applications.

Stainless steel mesh coatings are particularly valued for their ability to protect against environmental factors that can lead to degradation. This includes exposure to moisture, chemicals, and extreme temperatures. By applying specialized coatings, the mesh is better equipped to maintain its structural integrity and functionality over time. As industries continue to push the boundaries of what is possible, the role of stainless steel mesh coatings becomes increasingly significant.

Enhancing Corrosion Resistance

One of the primary benefits of stainless steel mesh coatings is their ability to enhance corrosion resistance. In many industrial environments, exposure to corrosive elements such as saltwater, chemicals, and pollutants is inevitable. Without adequate protection, stainless steel meshes can quickly succumb to rust and corrosion, compromising their structural integrity and performance.

Coatings specifically designed for corrosion resistance create a protective barrier on the surface of the mesh. This barrier prevents corrosive substances from reaching the metal, significantly extending the lifespan of the mesh. Industries such as marine, chemical processing, and wastewater treatment have seen substantial benefits from using coated stainless steel meshes. These coatings not only preserve the material but also reduce maintenance costs and downtime associated with corrosion-related repairs.

- Marine environments benefit from coatings that repel saltwater and prevent rust.

- Chemical processing plants use coatings to protect against aggressive chemicals.

- In wastewater treatment, coatings help maintain the functionality and longevity of filtration systems.

Improving Durability and Longevity

Durability is another critical factor in the selection of materials for industrial use. Stainless steel mesh coatings play a pivotal role in enhancing the durability of the mesh, ensuring it can withstand the rigors of demanding environments. The application of these coatings provides an additional layer of protection, making the mesh more resilient to mechanical wear and tear.

The improved durability translates to a longer lifespan for the mesh, reducing the frequency of replacements and repairs. This is particularly advantageous in industries where continuous operation is essential, and any downtime can result in significant financial losses. By investing in coated stainless steel meshes, companies can achieve a balance between performance and cost-effectiveness.

Furthermore, the coatings can be tailored to meet specific requirements, such as resistance to abrasion or impact. This customization ensures that the mesh can handle the unique challenges of its intended application, whether it’s in a high-traffic area or a location exposed to heavy machinery.

Supporting Filtration Processes

In addition to protection and durability, stainless steel mesh coatings play a vital role in supporting filtration processes. The mesh serves as a filter medium in various industrial applications, separating solids from liquids or gases. Coatings can enhance the mesh’s filtration capabilities by reducing clogging and improving flow rates.

For example, in water treatment facilities, coated meshes help ensure that filtration systems operate efficiently without frequent blockages. The coatings also make cleaning and maintenance easier, as they prevent particles from adhering to the mesh surface. This leads to more consistent performance and lower operational costs over time.

Industries such as food and beverage, pharmaceuticals, and oil and gas rely on coated stainless steel meshes to maintain high standards of filtration. The coatings ensure that the mesh can withstand the chemicals and temperatures involved in these processes, providing a reliable and effective solution for filtration needs.

Conclusion: The Versatile Solution for Industrial Applications

Stainless steel mesh coatings offer a range of benefits that make them an indispensable solution for various industrial applications. By enhancing corrosion resistance, improving durability, and supporting filtration processes, these coatings provide a comprehensive approach to addressing the challenges of harsh environments.

As industries continue to evolve and face new demands, the importance of reliable materials like coated stainless steel meshes cannot be overstated. They offer a balance of performance, longevity, and cost-effectiveness, making them a wise investment for any organization looking to optimize its operations.

In conclusion, the adoption of stainless steel mesh coatings is a testament to the innovative solutions available in modern industry. By leveraging these coatings, businesses can ensure their operations remain efficient, sustainable, and resilient in the face of adversity.