Honeywell XNX Gas Detector Calibration Solutions

Introduction to Honeywell XNX Gas Detector Calibration

In the world of industrial safety, the accuracy and reliability of gas detection systems are of paramount importance. The Honeywell XNX gas detector is renowned for its exceptional quality in monitoring various gases, ensuring safety in hazardous environments. Calibration of these devices is crucial to maintaining their accuracy and reliability. This article delves into the importance of calibrating Honeywell XNX gas detectors and the solutions available to ensure optimal performance.

Understanding the Calibration Process

Calibration is a critical process that adjusts the sensor of a gas detector to ensure it provides accurate readings. For Honeywell XNX gas detectors, calibration involves comparing the sensor’s output with a known concentration of gas and making necessary adjustments. This process is essential because over time, sensors can drift due to environmental factors, exposure to gases, or even normal wear and tear.

Key steps in the calibration process include:

- Setting up the calibration equipment properly and ensuring it’s functioning correctly.

- Introducing a known concentration of calibration gas to the detector.

- Adjusting the detector’s readings to match the known concentration.

- Documenting the calibration results for future reference.

Regular calibration helps in maintaining the detector’s accuracy, which is critical for ensuring the safety of personnel and equipment in potentially hazardous environments.

Solutions for Calibrating Honeywell XNX Gas Detectors

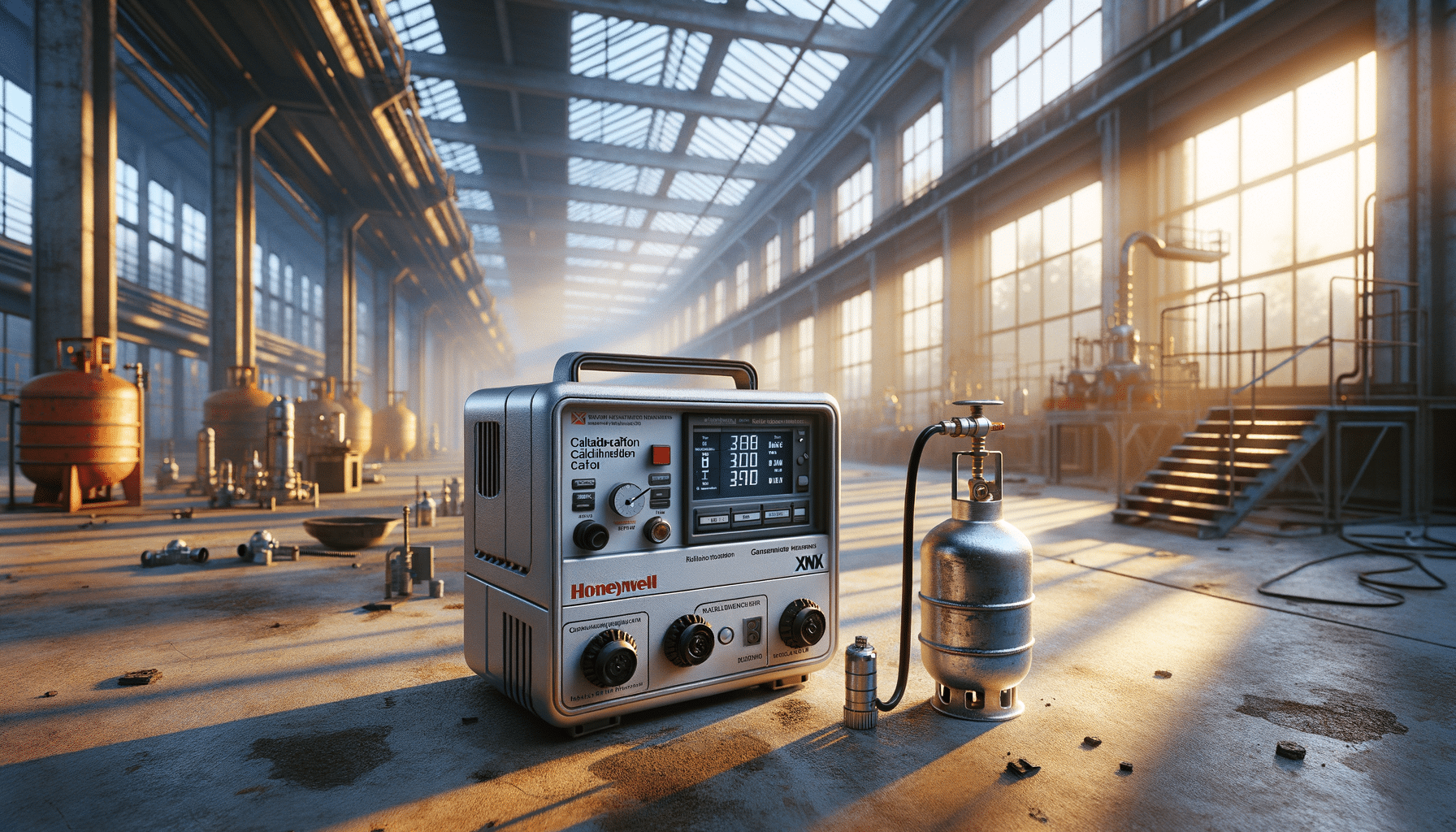

Several solutions are available for calibrating Honeywell XNX gas detectors, each catering to different needs and preferences. Portable calibration kits are popular for their convenience and ease of use, allowing on-site calibration without needing extensive equipment. These kits typically include a gas cylinder, regulator, and connecting hoses.

For more permanent setups, fixed calibration stations provide a reliable solution. These stations are equipped with automated systems that can perform regular calibrations without manual intervention, ensuring consistent accuracy over time. Additionally, they can be integrated with existing monitoring systems for seamless operation.

Outsourcing calibration services is another viable option, especially for companies without the resources to conduct in-house calibrations. Professional service providers offer expertise and specialized equipment, ensuring that calibrations are performed to the highest standards.

Benefits of Regular Calibration

Regular calibration of Honeywell XNX gas detectors offers numerous benefits, enhancing both safety and operational efficiency. By ensuring accurate readings, calibrated detectors prevent false alarms and missed detections, which can have serious consequences in industrial settings.

Accurate gas detection is vital for:

- Protecting personnel from exposure to harmful gases.

- Preventing costly downtimes due to false alarms.

- Maintaining compliance with safety regulations and standards.

Furthermore, regular calibration extends the lifespan of the detectors by ensuring they operate under optimal conditions, reducing the likelihood of sensor failure and the need for costly replacements.

Conclusion: Ensuring Safety and Accuracy

The Honeywell XNX gas detector is a critical component in safeguarding industrial environments. Ensuring these detectors are accurately calibrated is not just a regulatory requirement but a fundamental aspect of maintaining safety and operational efficiency. By understanding and implementing effective calibration solutions, industries can rely on their gas detection systems to provide precise and reliable monitoring, ultimately protecting both personnel and assets.

Whether through portable kits, fixed stations, or professional services, choosing the right calibration solution is essential for achieving the desired level of accuracy and reliability in gas monitoring.