How Much Does a Core Cutting Machine Cost?

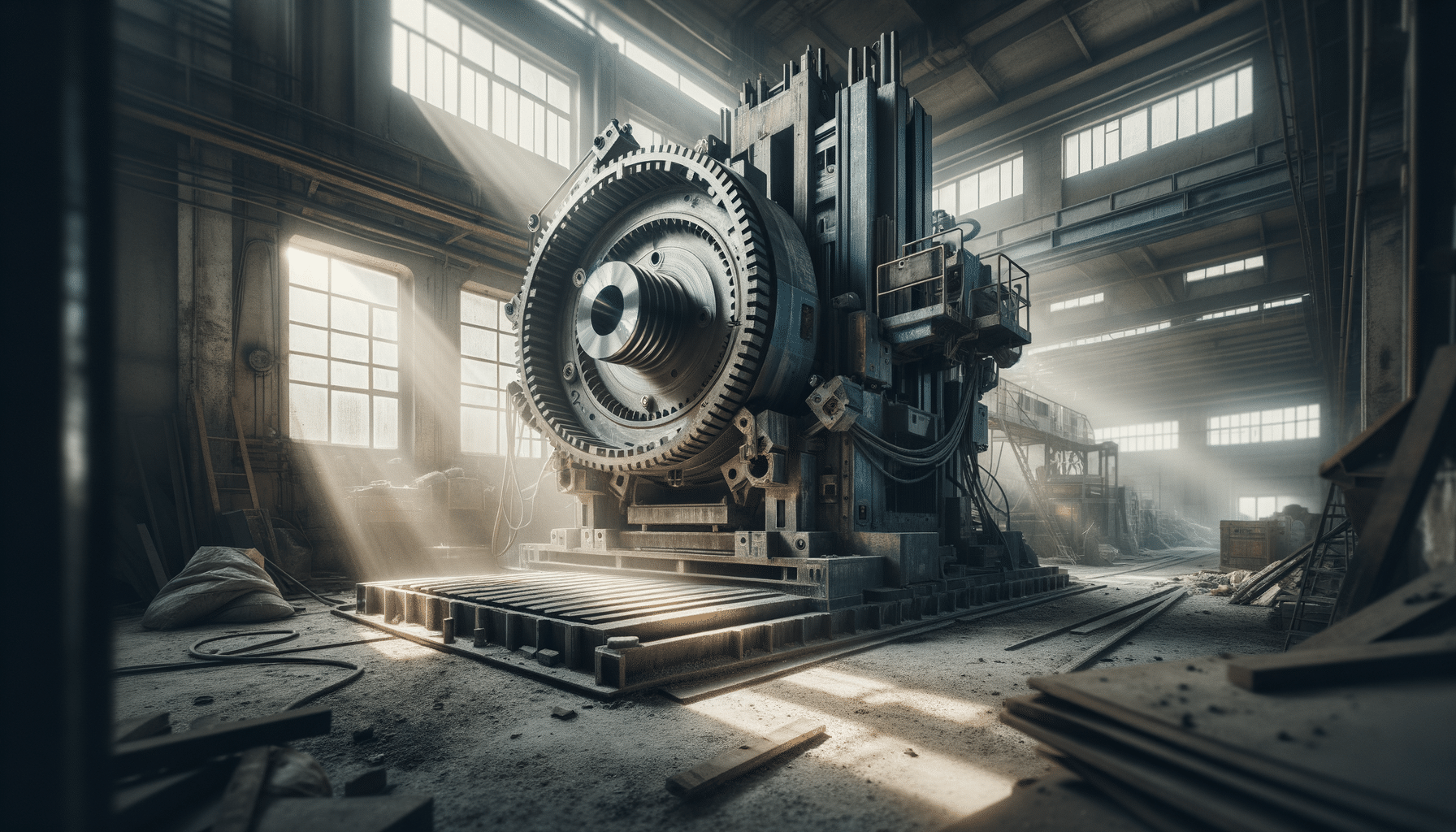

Introduction to Core Cutting Machines

Core cutting machines are essential tools in the construction and geology industries, designed to cut cylindrical samples from larger materials. These machines are crucial for analyzing the composition and structure of various materials, such as concrete and rock, providing valuable insights for construction projects and geological studies.

Understanding the cost of core cutting machines is vital for businesses and professionals who rely on precise material analysis. The price of these machines can vary significantly based on several factors, including power, build quality, and cutting depth. This article delves into the different aspects that influence the cost of core cutting machines, helping you make informed purchasing decisions.

Factors Affecting Core Cutting Machine Prices

The price of a core cutting machine is influenced by multiple factors, each contributing to the overall cost. Here are some of the key determinants:

- Power and Performance: Machines with higher power output can handle more demanding tasks, cutting through tougher materials with ease. These models are generally priced higher due to their advanced capabilities.

- Build Quality: Durable machines made from high-quality materials tend to be more expensive. However, they offer longevity and reliability, making them a worthwhile investment.

- Cutting Depth: The ability to cut deeper cores is a feature that can drive up costs. Machines designed for deep core cutting are typically equipped with more robust components and advanced technology.

- Brand and Manufacturer: Well-known manufacturers often charge a premium for their products, reflecting their reputation for quality and customer service.

- Additional Features: Features such as automation, digital controls, and enhanced safety measures can also affect the price, offering convenience and efficiency to users.

Understanding these factors can help buyers assess their needs and select a machine that aligns with their budget and operational requirements.

Typical Price Ranges for Core Cutting Machines

Core cutting machines come in a variety of models, each catering to different needs and budgets. Here’s a breakdown of typical price ranges you might encounter:

- Entry-Level Machines: Priced between $500 to $2,000, these machines are suitable for basic applications and light-duty tasks. They are ideal for small-scale projects or occasional use.

- Mid-Range Models: With prices ranging from $2,000 to $5,000, these machines offer a balance between performance and cost. They are well-suited for medium-sized projects requiring moderate power and depth capabilities.

- High-End Machines: Costing upwards of $5,000, these models are designed for heavy-duty applications and professional use. They feature advanced technology and robust construction, capable of handling the most demanding tasks with precision.

The choice between these ranges depends on the specific requirements of the project and the frequency of use. Investing in a higher-end model may be more cost-effective in the long run for professionals who require consistent performance and reliability.

Comparing Different Types of Core Cutting Machines

Core cutting machines come in various types, each designed to meet specific needs. Understanding the differences between these types can help buyers choose the right machine for their requirements:

- Manual Core Cutting Machines: These are operated manually and are typically more affordable. They are suitable for small-scale projects where precision and power are not the primary concerns.

- Automatic Core Cutting Machines: These machines offer automation features, enhancing efficiency and accuracy. They are ideal for medium to large projects and tend to be priced in the mid to high range.

- Hydraulic Core Cutting Machines: Known for their power and durability, hydraulic machines are used for heavy-duty applications. They are among the most expensive options but provide exceptional performance.

Each type has its advantages and is suited for different applications. Buyers should consider their project requirements, budget, and operational preferences when selecting a machine.

Conclusion: Making an Informed Purchase

Purchasing a core cutting machine is a significant investment, and making an informed decision requires careful consideration of various factors. By understanding the factors that influence price, typical cost ranges, and the differences between machine types, buyers can select a machine that meets their needs and budget.

Whether you are a professional contractor or a geology enthusiast, the right core cutting machine can enhance your work efficiency and accuracy. Consider your specific requirements, evaluate different models, and choose a machine that offers the best balance of performance, quality, and cost.