Top Tungsten Carbide Inserts Manufacturers in Europe

Introduction to Tungsten Carbide Inserts

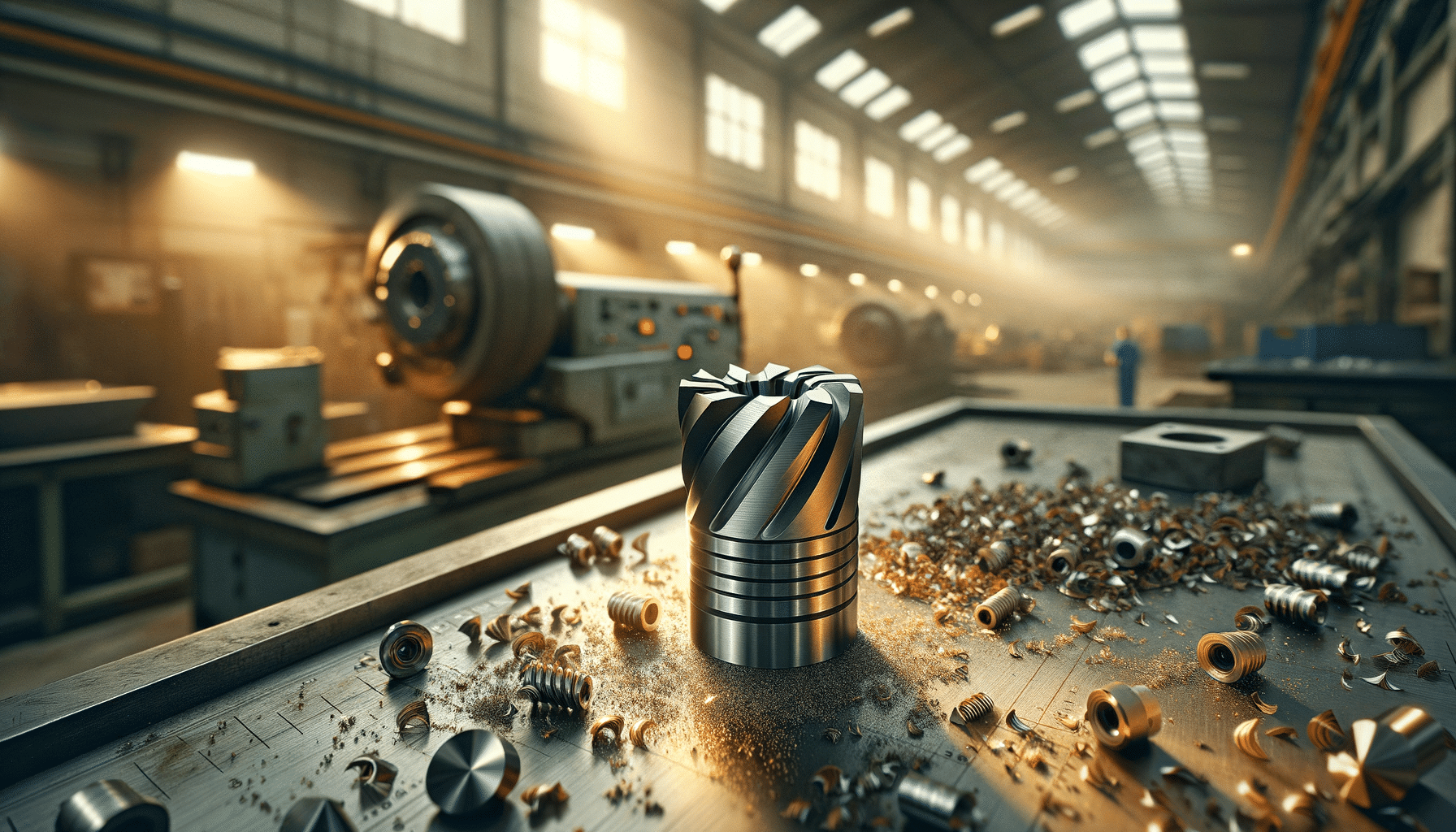

Tungsten carbide inserts are an integral component in the manufacturing industry, known for their remarkable hardness and durability. These inserts play a crucial role in metal cutting and machining applications, providing precision and efficiency. Europe has a rich history of manufacturing excellence, and its tungsten carbide inserts manufacturers are renowned for producing high-quality products that meet the rigorous demands of various industries. This article explores some of the leading manufacturers in Europe, highlighting their contributions to innovation and quality in the field.

Key Characteristics of Tungsten Carbide Inserts

Before delving into the manufacturers, it’s essential to understand what makes tungsten carbide inserts so valuable. These inserts are composed of tungsten carbide, a chemical compound made from tungsten and carbon. The result is a material that boasts exceptional toughness and resistance to wear and tear, making it ideal for cutting tools. The primary characteristics that set tungsten carbide inserts apart include:

- Hardness: Tungsten carbide is much harder than steel, providing a longer lifespan for cutting tools.

- Heat Resistance: These inserts can withstand high temperatures, maintaining their integrity during intense machining processes.

- Precision: Their ability to maintain sharp edges ensures high precision in cutting applications.

- Versatility: Suitable for a wide range of materials, from metals to composites.

These attributes make tungsten carbide inserts a preferred choice for industries requiring reliable and efficient cutting solutions.

Leading European Manufacturers

Europe is home to several esteemed manufacturers of tungsten carbide inserts, each contributing to the industry’s growth through innovation and quality production. Some of these manufacturers include:

- Company A: Known for its advanced research and development, Company A has consistently delivered cutting-edge solutions that meet the evolving needs of the market.

- Company B: With a focus on sustainable practices, Company B integrates eco-friendly methods into its manufacturing processes, ensuring minimal environmental impact.

- Company C: Renowned for its customer-centric approach, Company C offers customized solutions tailored to specific industrial requirements, enhancing operational efficiency.

These companies not only provide exceptional products but also drive innovation, setting benchmarks in the industry.

Technological Advancements and Innovation

The European tungsten carbide inserts industry is characterized by continuous technological advancements and innovation. Manufacturers invest heavily in research and development to enhance the performance and efficiency of their products. Recent innovations include:

- Coating Technologies: Advanced coatings are applied to inserts to further improve their wear resistance and longevity.

- Precision Engineering: Enhanced manufacturing techniques ensure higher precision and consistency in product quality.

- Smart Manufacturing: Integration of IoT and AI in production lines to optimize processes and reduce downtime.

These advancements not only improve product quality but also contribute to the competitiveness of European manufacturers on the global stage.

Conclusion: The Future of Tungsten Carbide Inserts in Europe

As the demand for high-performance cutting tools continues to grow, European manufacturers of tungsten carbide inserts are well-positioned to lead the industry. Their commitment to quality, innovation, and sustainability ensures they meet the evolving needs of various sectors, from automotive to aerospace. By leveraging cutting-edge technologies and maintaining a focus on customer satisfaction, these manufacturers will continue to play a pivotal role in shaping the future of the manufacturing industry.